Emergency? Call us now

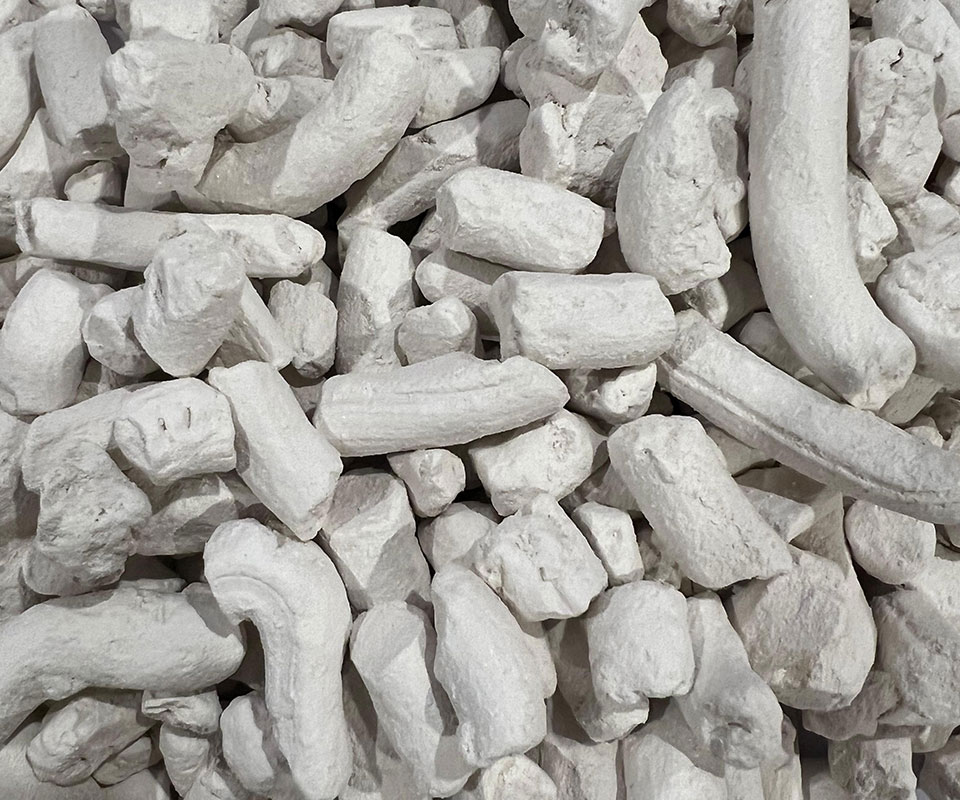

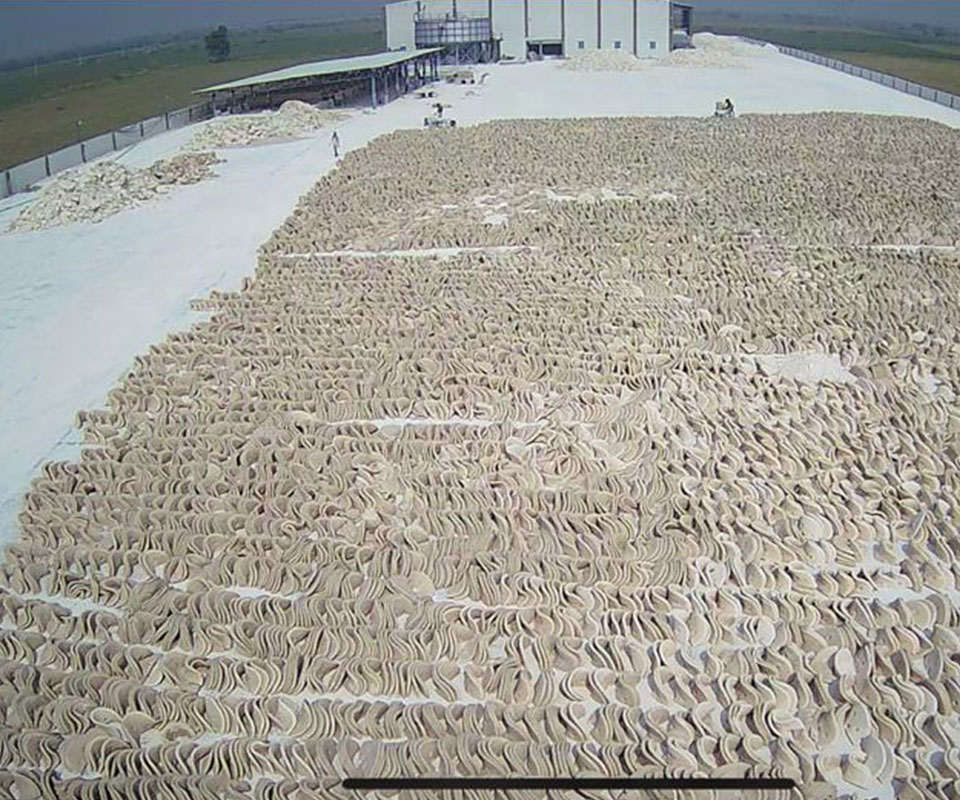

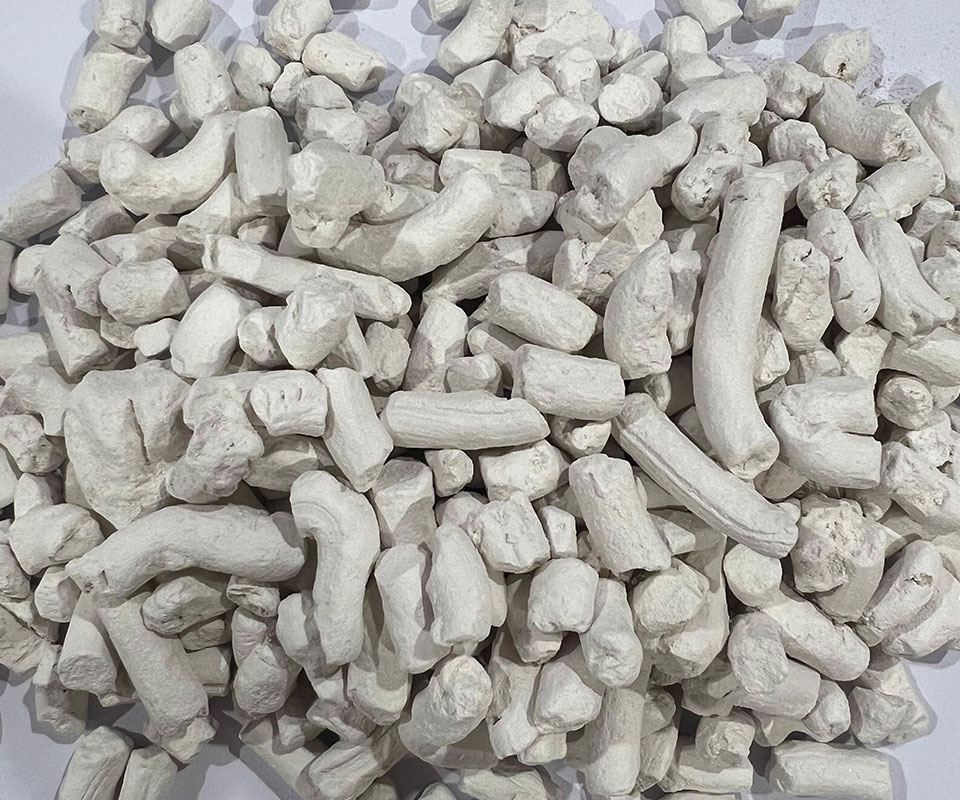

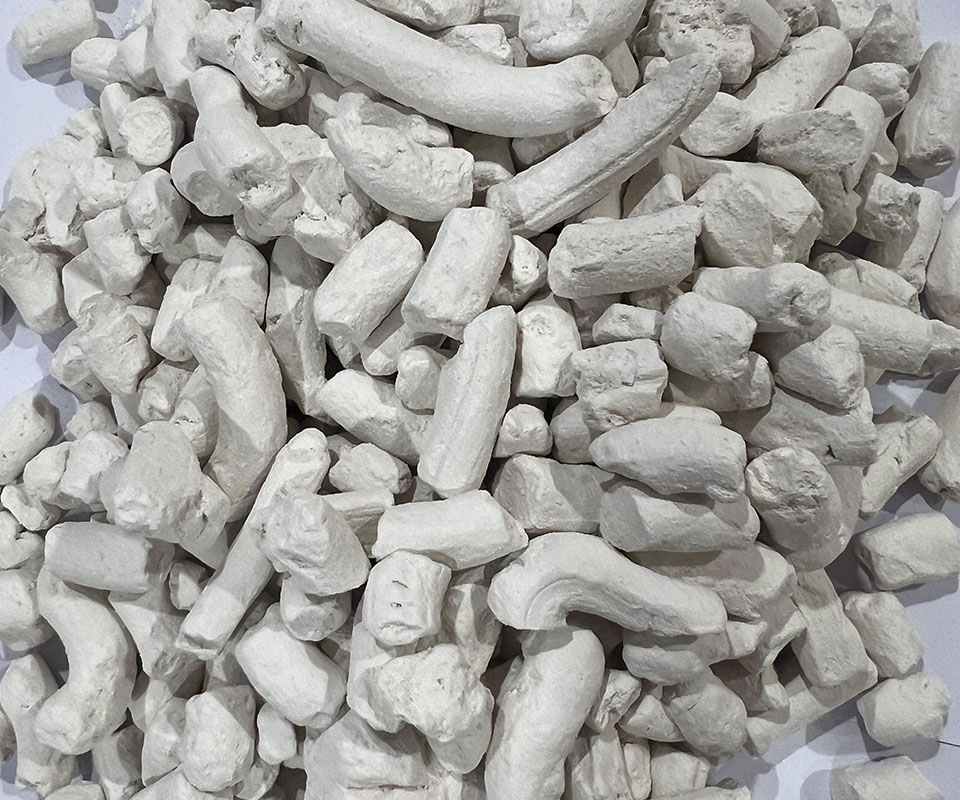

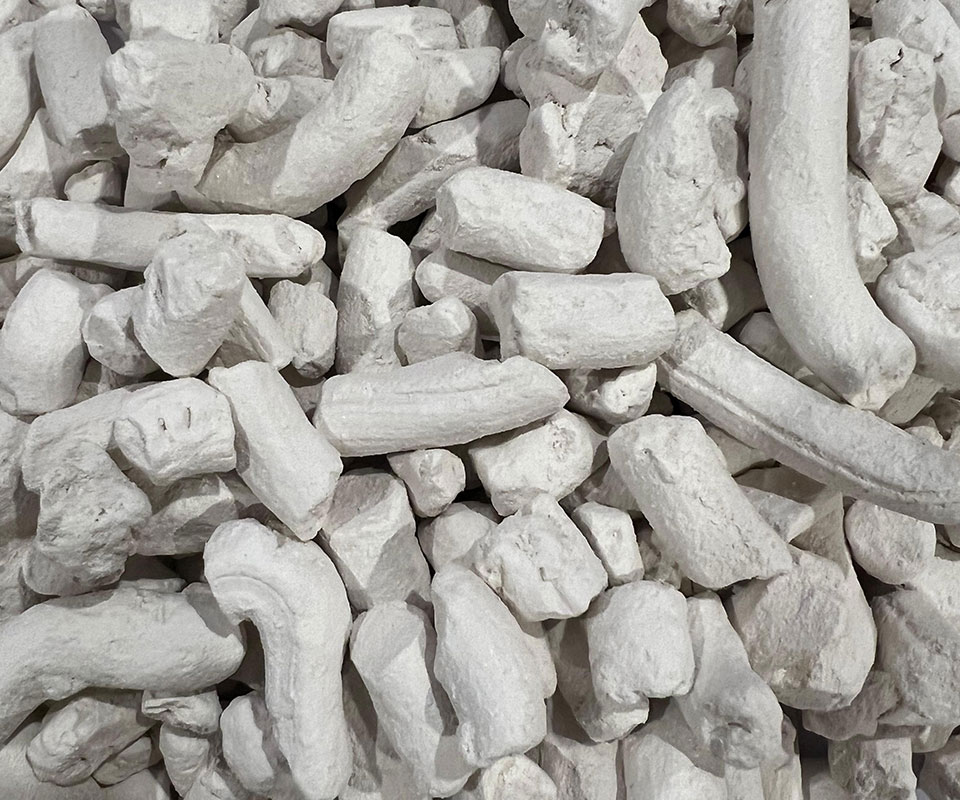

Kaolin is one of the more important industrial clay minerals. Kaolin is comprised predominantly of the mineral kaolinite, a hydrated aluminum silicate. Kaolinite, which is the dominant mineral in kaolin deposits, is a common clay mineral, but the relatively pure and commercially usable deposits are few in number. Kaolinite has physical and chemical properties which make it useful in a great number of applications. One of the most important applications of kaolin is coating and filling paper. As filler, the kaolin is mixed with the cellulose fibers in wood pulp and as a coating; the kaolin is mixed with water, adhesives, and various additives and coated onto the surface of the paper. The coating makes the paper sheet smoother, brighter, glossier, more opaque, and most importantly, improves the printability. Paper that is not coated is made up of cellulose fibers interwoven in a random and open configuration.

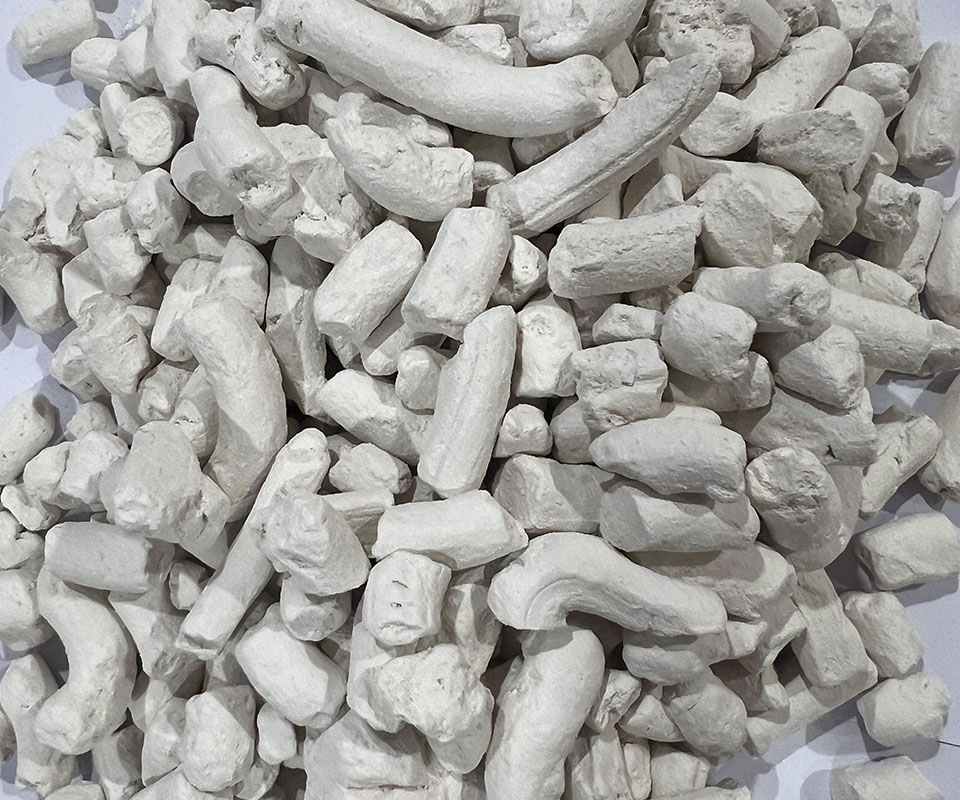

Kaolin, a type of clay known for its fine particle size and plasticity, is commonly used in the ceramic industry. Its presence in ball clay enhances properties like strength and workability, making it an essential component in the production of ceramic tiles and sanitary ware. With its ability to improve the firing characteristics and color of ceramics, kaolin plays a crucial role in achieving desired aesthetics and performance standards.

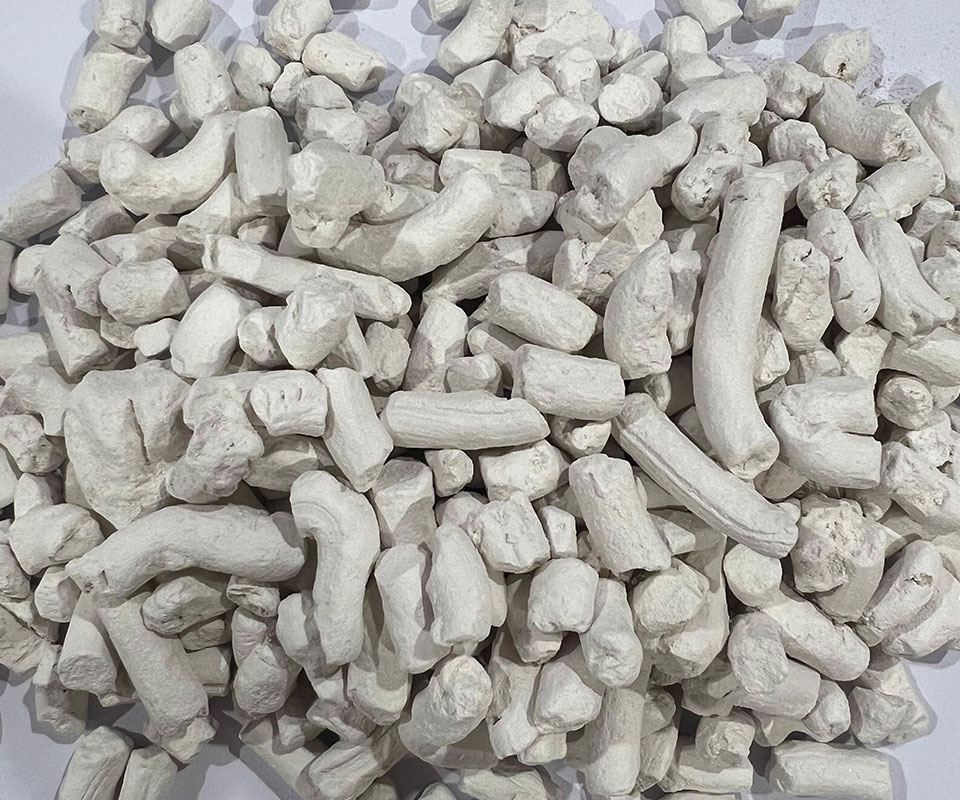

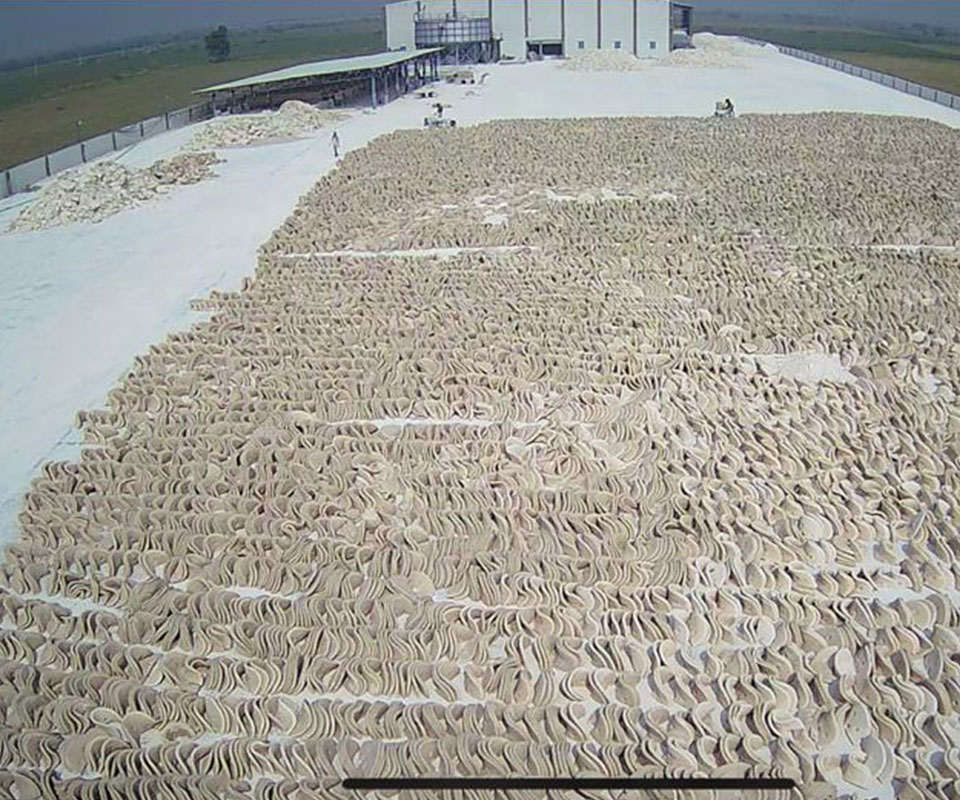

Yes Group Of Minerals have a wide range and many different grades of Kaolin.

Industries : Tiles, Sanitary Ware, TableWare, Insulator, Refractories, Paint Industries, Paper Industries, Glass Industries, Cosmetic etc.

Highly controlled rheology

Highly controlled casting rate and deflocculant demand

Good dry strength

Excellent particle packing and associated good production yields

Outstanding whiteness

Improved resistance to deformation